Vibgyor Automotive is an IATF 16949 company, meeting all global standards and quality requirements. All the individual plants are also certified by

ISO 9001:2015 along with customer audit requirements.

At Vibgyor, we practice "Digital Quality Manufacturing System" (DQMS) in line with Industry 4.0

In house quality lab for ensuring the products are meeting customers requirement.

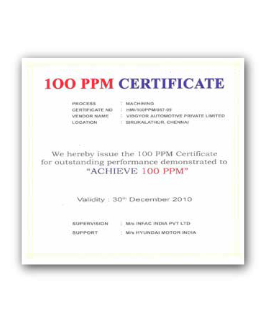

Customer quality standards like IATF 16949, IMaRQ, SQ Mark, 100 PPM, Zero Defect, VSA are met

We follow Flow line, JIT, Synchron, Kanban, Cell concept for our component manufacturing process

CFT, Gemba, TPM, Poke Yoke, IPC, QFD, Kaizan, Change management and APQP are practised to achieve process robustness and product consistency

Inspection Facility

Cutting, Polishing, moulding machine for mould preparation for heat treated component testing

Abrasive Cutting Machine

General Purpose Belt Grinder

Hydraulic Specimen Mounting press

Single Disc Variable Speed Grinder-Polisher

Micro Vickers Hardness Tester

Profile Projector

Crack Deduction Tester

Metrology lab

Certifications

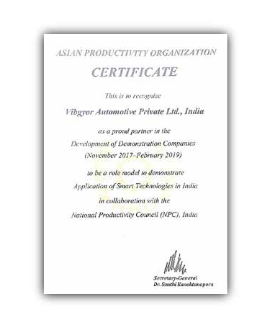

Smart Manufacturing Industry 4.0 - Certification

IATF Certificate

100 PPM Certificate

Rane Best Supplier Award - 2017

Awards

Rane Best Supplier Awared 2017

TAFE Best Supplier Award 2018

International Achievers Award 2017

LUCAS TVS Deming Prize 2004

INFAC Appreciation Award 2009

Smart Manufacturing - Demonstration at Taiwan

Smart Manufacturing Industry 4.0 - Award by APO & NPC - 2019

Rane Best Supplier Award - 2016